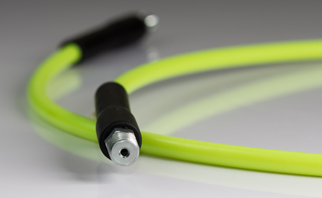

Crimping hydraulic hoses

The production and service of high pressure hydraulic hose assemblies provided by Tubes International is our chief asset.

For years we have been supplying superior solutions as a result of our close cooperation with the world’s leading manufacturers. As far as high pressure hydraulic hose assemblies are concerned, our production is entirely based on EU producers.

We produce high pressure hydraulic hose assemblies of all kinds – from standard rubber hoses, thermoplastic hoses, PTFE hoses, to highly specialised ultra-high pressure hoses – up to 3200 bar.

We easily handle serial production but also single items according to Customer specification.

Fast production

Each of our branches is equipped with both cutting device and crimping machine ready to crimp high pressure hydraulic hose assemblies. That is why we can supply hose assemblies (hydraulic, thermoplastic, PTFE and many other), within the shortest possible time.

Production of hose assemblies up to 3200 bar

In our workshops we manage the production of ultra high pressure hose assemblies including multispiral thermoplastic hose assemblies with working pressure as high as 3200 bar, rubber hoses for water cutting and cleaning, with working pressure reaching 1400 bar.

Hose assembly protective covers

We also offer a range of hose protective covers (metal, heat shrinkable, plastic, fabric, thermal), which significantly extend the service life of produced hose assemblies.

Easy identification of each hose assembly

We can ensure that everyone who uses our services gets the hose assemblies of the highest quality. Either a single piece or a batch is marked to enable easier identification in the future. On Customer request we provide our hose assemblies with quality certificates.

Production of customized fittings

At Tubes International we have our own production department, where we can manufacture all kinds of hydraulic fittings according to Customer specifications.

Other services – hydraulic hose assemblies

- testing with static pressure (water or hydraulic fluid)

- cleaning by shooting cleaning projectiles

- protection against contamination (e.g. sealing with heat-shrink capsules)